Proton Therapy Vault for Cutting-Edge Treatments

Proton Therapy Vault for Cutting-Edge Treatments

After reviewing the architectural plans, we bid this project to a contractor that would be constructing an additional Proton Therapy Vault for cutting-edge radiation treatments. A lead-lined wall needed to be integrated into the structure to protect patients and medical staff. Clearly, no detail could be overlooked on a project like this.

The Project: Proton Therapy Vault for Cutting-Edge Treatments

After reviewing the architectural plans, we bid this project to a contractor that would be constructing an additional Proton Therapy Vault for cutting-edge radiation treatments. A lead-lined wall needed to be integrated into the structure to protect patients and medical staff. Clearly, no detail could be overlooked on a project like this.

This design included:

- A 3-faced facade of layered lead walls to protect patients and hospital personnel from radiation.

- Leaded glass panes overlapping the lead lining for the operator to see through to treat the patient.

- A lead equivalence solution to meet the requirements for protection with the equipment being used.

The Challenges

This project underwent several design phases and updates to accommodate the customers’ final needs.

- Our first challenge was to design a 3-faced facade with removable panels to accommodate the glass installation on site. We knew that this vault would protect medical technicians from radiation damage, so there was no room for error.

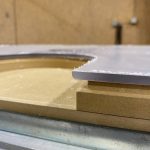

- The overall thickness of the wall was closely contemplated and reviewed to accommodate conduits, mounting plates to tie into the ceiling, and the layers of lead lining needed so that no raw material would be exposed but, instead, clad in plastic laminate.

- The last challenge was maintaining structural stability while installing a final product that weighed approximately 850 lbs.

As we planned this project, we discovered that the details were key.

The Solution

Detailed Planning and Installation for a Precise and Pristine Treatment Room Shield

Solution 1: From the start of this project, we created our own shop drawings to plan in intricate detail what we interpreted from the architectural plans, showing how we wanted every piece fabricated. The design underwent several architectural supplemental instructions (ASIs), revisions, and reviews to refine the details into a finished plan ready for assembly and fabrication. The lead thickness and how to avoid excessive cutting, folding, and overlapping would be critical to achieving the proper thickness of the structure.

Solution 2: DH Schmidt had some experience with projects like this because we constructed the first proton vault in this area. As this project was designed, we looked back at our original fabrication drawings and photos and made adjustments based on what we had learned. Our goal was to make it easy for our fabricators to layer the lead, while also maintaining the design intent and function.

Solution 3: The last step was installing this structure. Because it was designed as one piece to avoid seams and breaks in the lining, we needed to fabricate a custom mobile cart, so we could move it with ease. Our customer asked that we design this mobile cart in a way that would allow it to both pivot across a step down in the floor and maintain safe and secure handling.

The Final Product

An Improved, Innovative Design to Support Medical Treatments

Beyond custom, this project took abundant design time to address every detail and develop a visually appealing and functional fixture. We were able to overcome challenges in design and coordination and provide a suitable solution for every party – from the architect to the contractor to our design team and fabricators, and even to our vendors and our contractor’s vendors.